EQUIPMENT:

Tower Crane

LOCATION:

Birmingham

OPERATION:

26 Storey Building Construction

The Radius Group team were tasked by repeat client BAM to provide tower cranes for the 103 Colmore Row project in the heart of Birmingham. The project involved the construction of a 26-storey building at 103 Colmore Row in Birmingham. The building boasts a winter garden, an 18th-floor terrace, and multi-purpose lobby business lounges. At the time of construction it was the tallest office building outside London, standing at a height of 108m and 246m above sea level.

Before the construction could begin, an existing building (Natwest Tower) needed to be demolished. Radius Group partnered with H Smith Demolitions in 2015 for the demolition, utilizing our expertise and an MDT368-L16 topless tower crane. Our experience and technical execution proved invaluable in the eyes of the major stakeholders.

108M

246m

Tie and Climb

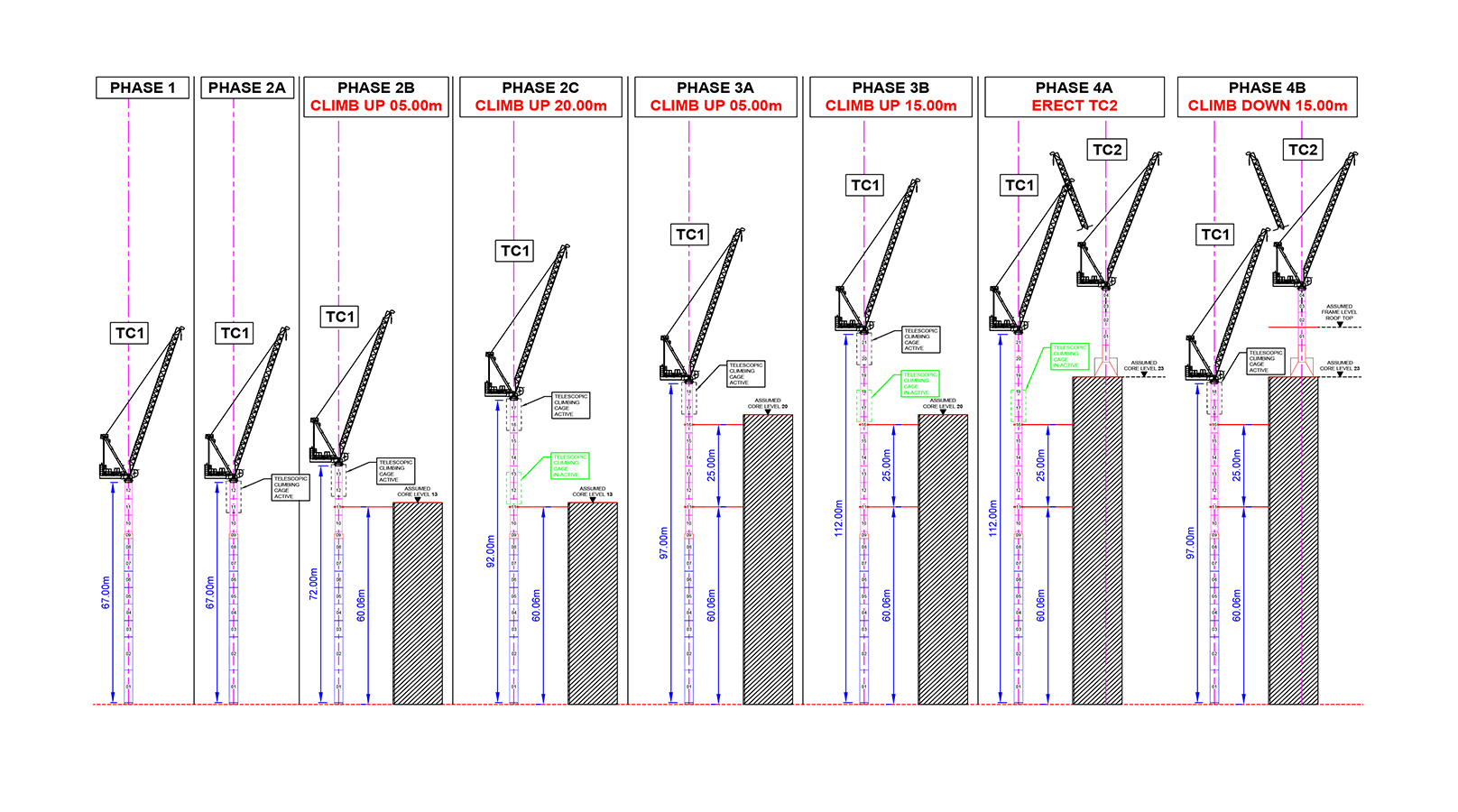

Due to the nature and height of the build, TC1 was used for the first stage of construction. The telescopic cage was installed at 67m, and the crane climbed to 72m before the installation of the first modular tie to the building core. As the building continued to rise, the second modular tie was added at 85m. Eventually, for the final build phase, TC2 was erected, by TC1.

Collaboration with Morrisroe

Essential communications and liaison were maintained with Morrisroe throughout all phases. Morrisroe was responsible for technical checks on the building core to ensure structural integrity and acceptable deflections. With their expert guidance, we monitored when the formwork would be at the correct level before we could progress with the tie and climb exercise. Morrisroe were also responsible for the technical checks on the core, to ensure the structural integrity of the building core was not compromised and make sure that all deflections were within tolerable limits.

Tower Crane Dismantle

One of the biggest challenges of the project was the dismantle of TC2. A large part of Birmingham had to be shut down in order to bring a 1000te mobile – the largest crane ever brought into the city – which required meticulous planning and extensive traffic management.

Traffic Management and Coordination for TC2 Dismantle

Extensive traffic management measures, including diversions and road closures, were implemented in collaboration with Birmingham City Council. Traffic management spanned from 3rd to 7th December 2020. We successfully minimised disruption to the road network, whilst maintaining the utmost safety measures for the area. Numerous traffic marshals were present every day. The positioning of the mobile was planned meticulously and precisely using with global coordinates.

Technical Expertise & Recognition

The project showcased technical expertise, attracting visits from overseas engineers and being featured in Potain’s product guide. Overall, the project stands out as a successful example of collaboration, technical execution, and precision in construction and demolition processes.

Small Mobile Crane for Building a Big Mobile Crane

Using a smaller mobile crane to construct a larger one is a common practice in the construction industry. Due to the restricted site, it was the only option for facilitating the assembly of components.

3D Simulation for Safety Precaution

Simulating the entire operation in 3D before implementation allowed our engineers to identify potential risks, address challenges, and optimize the process before physically executing it. This exercise was essential due to the varying building heights of neighboring properties.

Radius Group are a dedicated team of experienced site specialists backed by an industry-leading technical department. We offer a comprehensive ‘turnkey’ service, from initial consultation to project completion.